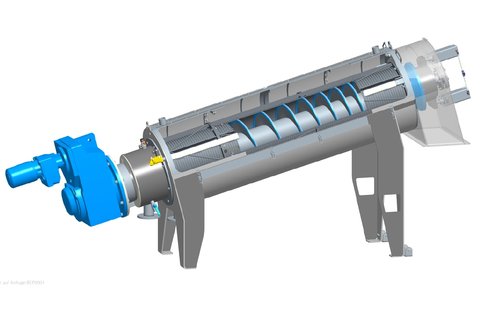

screw press

|

A Dewatering screw press is a press that separates liquids from solids. A screw press can be used in

place of a belt press or centrifuge. It is a simple, slow-moving device that accomplishes dewatering by continuous gravitational drainage. Screw presses are often used for materials that are difficult to press, for example, those that tend to pack together. |

The screw press squeezes the material against a screen or filter and the liquid is collected through the screen for collection and use.

In the first part of the screw press, the supernatant is quickly removed by a large filter surface at a low primary pressure. A pressure probe in the feed area controls the primary pressure thus ensuring a constantly high filtrate quality.

In the first part of the screw press, the supernatant is quickly removed by a large filter surface at a low primary pressure. A pressure probe in the feed area controls the primary pressure thus ensuring a constantly high filtrate quality.

|

In the third part of the screw press, the residual water is pressed out of the sludge, at a minimum

filter cake thickness, by the pneumatic counter pressure cone at the press discharge. The dewatered sludge is pushed by the conveying screw past the pressure cone into the discharge chamber. The sludge residence time in the screw press and thus the filtration time can be adjusted to individual requirements by adjusting the rotational speed of the screw shaft. |